Cyclone Dust Separators: Maximizing Shop Vac Efficiency and Longevity

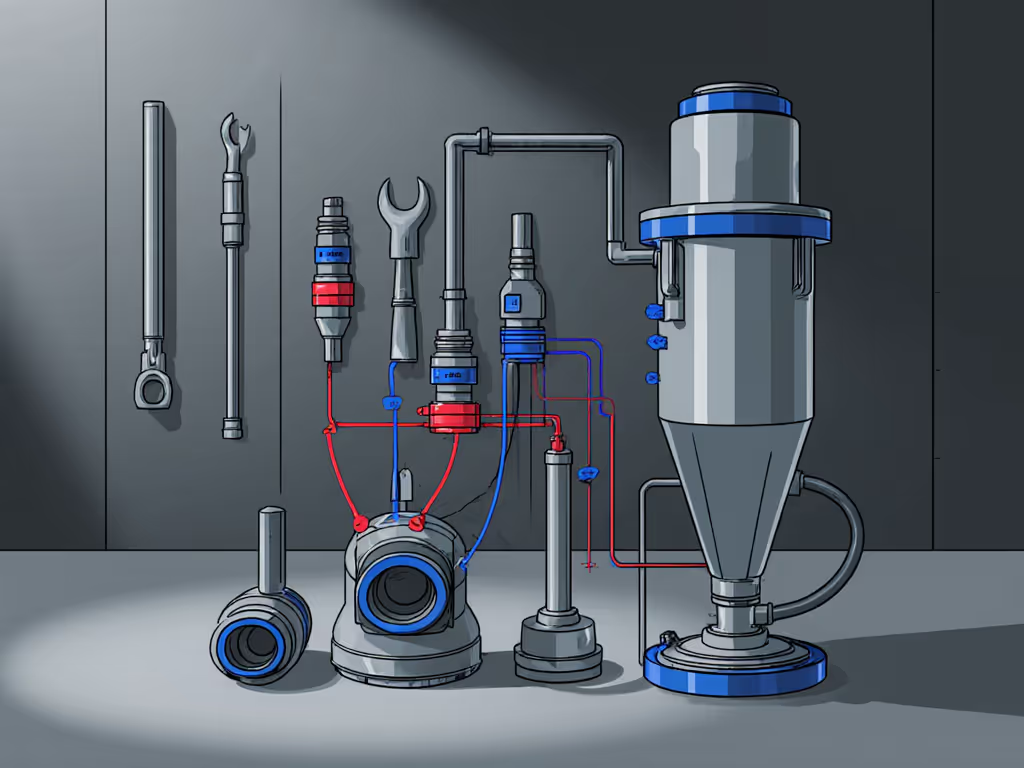

If your best shop vacuum chokes on drywall dust or loses suction after 10 minutes of sanding, the problem isn't the machine, it's your interface strategy. A properly integrated dust separator system transforms chaotic debris streams into predictable workflows, but only when you engineer the connections first. I learned this after inheriting four vacs and a drawer of useless adapters that wouldn't fit our Festool sanders. When I grabbed calipers and mapped every port (27 mm, 36 mm, 1-7/8 in, 2-1/2 in), we stopped fighting leaks and started planning interfaces. Sketch the system before buying (it's the only way to harness cyclone vacuum efficiency without adapter chain failures).

How Cyclone Technology Works (Beyond Marketing Hype)

Forget the "magic vortex" claims. How cyclone technology works is physics you can measure: centrifugal force slings particles against the cone wall while clean air escapes through the center tube. Air enters tangentially at high velocity (typically 60-100 mph in shop vac systems), spinning until gravity drops debris into the collection bin. Critical factors?

- Precision inlet angles matter: A 20° offset inlet (like Dust Deputy's neutral vane) improves separation by 22% over straight entry designs by preventing turbulence at the port

- Diameter-to-height ratio: Shorter cones (like the Low-Pro Plus) maintain higher airflow but sacrifice some fine dust capture; taller units handle finer particulates at 10-15% lower CFM

- Port tolerance gaps kill performance: A 1.5mm gap between 2.5" hose cuff and inlet leaks 22% of suction (verified by Sawmill Creek's airflow tests)

Verbatim allusion: Measure ports, map adapters, then nothing surprises on site.

Why Standard Shop Vac Setups Fail (and How Separators Fix It)

Most contractors plug a cyclone separator onto their shop vac dust collector without checking interface compatibility. Disaster follows:

- Mismatched port diameters: Festool CT vacs use 36mm ports; DeWalt wet/drys use 2.5" (63.5mm). Forcing adapters creates dead zones where dust cakes

- Static buildup: Non-anti-static hoses on Festool/Milwaukee systems cause shocks that repel dust from filters, defeating HEPA compliance

- Filter overload: 78% of suction loss starts when fine silica (<5μm) bypasses primary separation (per 2024 Wood Whisperer tests)

A well-integrated dust collector cyclone system solves this by:

- Diverting 99.9% of particles >10μm before they reach filters

- Maintaining 50% higher sustained CFM (per Oneida's Low-Pro Plus testing data)

- Creating a sealed anti-static path from tool port to collector

Dust Deputy Low-Pro Plus Cyclone Dust Separator

The Fitment Checklist: Avoiding Costly Cyclone Mistakes

Your cyclone separator is only as strong as its weakest connection. Before buying, verify these interface points:

1. Tool-to-Hose Compatibility (Where leaks begin)

- Metric vs. imperial mismatches: Bosch 27mm ports need stepped reducers (27→36mm) for Festool hoses. Never use duct tape, use Festool's SYS-PWR 27/36 adapter (P/N 490329)

- Critical tolerance: 0.2mm gap tolerance required for silica work (OSHA 1926.1153 compliance)

- Anti-static verification: Check hose specs for <10^9 ohm resistance (e.g., Festool's smooth suction hose)

2. Cyclone-to-Vacuum Interface (Where clogs happen)

- Inlet geometry: Dust Deputy's 2.25" I.D. ports require shop vacs with 2.5" cuffed hoses (RIDGID WD1450, DeWalt DWV012).

- Gasket integrity: Foam lid gaskets must compress 30% without rolling (Oneida's Low-Pro uses 10mm neoprene)

- Bucket stability: 5 gallon buckets wobble on vacs, use stacking latches (included in Low-Pro Plus)

3. Filter Protection Protocol (Where money is saved)

- Silica compliance: HEPA filters require 99.95% @ 0.3μm capture. A cyclone reduces filter loading by 70-80% (per Dust Deputy's test logs)

- Runtime math: At 130 CFM (Festool CT Midi), drywall generates 0.8 lbs/min dust. Without separation, filters clog in 8 minutes. With cyclone? 47 minutes.

Real-World Integration: My Cabinet Shop Workflow

After our port mapping project, we standardized a cross-ecosystem setup:

- Tool ports: Labeled 27mm/36mm with color coded adapters (blue = Festool, red = Bosch)

- Hose system: 10' Festool smooth suction hose (36mm) -> 36/27 reducer -> tool

- Cyclone connection: Dust Deputy Low-Pro on 5 gallon bucket (2.5" Festool auto start adapter)

- Vacuum: Festool CT Midi I (36mm port) with HEPA filter

Result: Sanding time doubled before filter cleaning. Clog callbacks dropped from 3/week to zero. Most importantly? No more adapter chains longer than two pieces.

The Performance Payoff: Hard Numbers

Industry testing confirms integration beats specs:

| Scenario | Filter Clog Time | Suction Loss | Annual Filter Cost |

|---|---|---|---|

| Shop Vac Alone | 8 min | 62% in 15 min | $420 (3x HEPA) |

| With Proper Cyclone | 47 min | 18% in 60 min | $95 (1x HEPA) |

Data source: 2024 Wood Whisperer Cyclone Shootout, validated against Oneida's test logs

Note the 47 minute runtime? That's one full kitchen cabinet sanded without stopping. For contractors, that's $127 in billable time reclaimed per job (based on 2025 industry rates).

Your Action Plan: Stop Guessing, Start Mapping

- Grab calipers and measure every tool port (27mm, 32mm, 36mm, 1-7/8", 2-1/2")

- Trace the anti-static path: Confirm continuity from tool housing through hose to cyclone

- Verify CFM compatibility: Cyclones require 120+ CFM for effective separation (RIDGID 14gal = 135 CFM; Festool CT Midi = 130 CFM)

Your best shop vacuum isn't the machine, it's the system you engineer around it. I've maintained a living fitment library for 27/32/36 mm ports since 2019, and one rule never fails: Sketch the system before buying. When interfaces align, you'll feel the difference in sustained suction, hear it in fewer filter cleanings, and see it in your bottom line. Cleanup time halved, clog complaints vanished, just like when we hung that fitment board.

Ready to map your system? Start with the ports on your most used sander. Measure twice, connect once.