Best Low-Noise Shop Vacuums: Hearing-Safe 2025 Comparison

When your best shop vacuum operates at screaming decibel levels, it's not just annoying; it's a compliance risk and a health time bomb. And while "cool vacuum cleaner" might sound like marketing fluff, it's actually mission critical for job sites near occupied homes, schools, or healthcare facilities. As a former site safety coordinator who has seen drywall dust turn into OSHA violations in minutes, I know noise isn't just about comfort. It is about whether your crew wears hearing protection consistently (they won't if it's uncomfortable) and whether your client tolerates your presence during remodels. Containment first; cleanup is the insurance your lungs deserve. Below, I map your hearing protection vacuum needs to verified decibel levels shop vac specs, and the noise reduction techniques that actually work on real job sites.

Why Noise Matters More Than You Think

Tradespeople ignore vacuum noise at their peril. Consumer Reports confirms most standard shop vacs run at 80-90 dB (equivalent to a miter saw at idle). But here's what manuals won't tell you: OSHA's permissible exposure limit is 85 dB for 8 hours. At 90 dB, that drops to 2 hours before mandatory hearing protection kicks in. Miss that window during a long demo job, and you're risking fines and permanent hearing damage. I learned this the hard way when a masonry crew dry-cutting concrete triggered a $12,000 citation. Their vac sounded "fine" but lacked HEPA filtration and was so loud no one wore ear protection. The dust cloud? Just the visible tip of the iceberg.

For your daily reality, prioritize these noise thresholds:

- <70 dB: Safe for 8+ hours without hearing protection (ideal for occupied spaces)

- 70-80 dB: Requires intermittent ear protection during multi-hour jobs

- >80 dB: Mandatory hearing protection immediately, and client complaints will follow

Remember: Advertised specs often lie. Always verify real-world decibel levels shop vac performance with a NIOSH Sound Level Meter app before buying.

Step 1: Decode Noise Reduction Claims (Without Getting Hyped)

Manufacturers love "quiet" labels, but too many cut corners. Here's how to spot genuine hearing protection vacuum technology versus marketing spin. Use this pre-flight checklist:

| Feature | Pass/Fail Criteria | Why It Matters |

|---|---|---|

| Verified dB Rating | Must include distance (e.g., "65 dB at 3 ft") | Ridgid's muffler dropped their vac to 82 dB, but the tone changed, not the actual exposure risk (per FineWoodworking's field tests) |

| Sealed Motor Housing | Zero visible gaps around motor casing | Unsealed units leak high-pitched whine that damages hearing faster than low-frequency hum |

| Dual-Stage Filtration | HEPA filter + pre-motor foam sleeve | Filters muffle sound and prevent the dreaded "suction scream" when clogged |

| Anti-Vibration Mounts | Rubber grommets isolating motor from tank | Stops structural resonance that amplifies noise by 5-10 dB |

My cardinal rule? Seal every joint on purpose. I once watched a $500 vac hit 87 dB because the hose adapter wasn't locked. That tiny air leak turned a "quiet" unit into a hearing hazard. Always test the entire system (hose, tools, and adapters), not just the bare unit.

Step 2: Top 3 Hearing-Safe Vacuums Verified for 2025

After cross-referencing lab tests, field reports, and my own pre-job site inspections, these models deliver proven noise reduction techniques without sacrificing suction. I prioritized units with documented dB ratings and OSHA-ready filtration.

RIDGID 4000RV 4-Gallon Compact

This isn't your grandpa's screaming shop vac. At 70 dB (verified at 3 ft), it's the quietest affordable option for detailers and small-crew contractors. The secret? A sealed motor housing plus RIDGID's patent-pending muffler/diffuser that redirects exhaust downward (critical for mobile detailing where blowback annoys clients). Its 5.0 Peak HP motor moves 150 CFM, enough to handle drywall dust with the included fine-dust cartridge filter.

Why trades choose it:

- Fits in car trunks (15" tall, 14.5 lbs)

- Onboard storage for 8' hose + car nozzle

- Qwik Lock filter system avoids clogs mid-job

RIDGID 4000RV 4-Gallon Wet/Dry Compact Vacuum

Vacmaster Beast Series 5-Gallon

For solo contractors drowning in drywall or concrete dust, this 72 dB beast delivers Festool-level filtration at half the price. Its high-efficiency cartridge filter traps particles down to 1 micron (essential for silica compliance). Unlike "quiet" vacs that sacrifice suction, the 320 Air Watt motor maintains 120 CFM even when filtering HEPA-level dust. The noise reduction techniques shine here: kink-resistant hose reduces turbulence noise, while oversized latches seal joints that cause high-pitched leaks.

Pro tip: Pair it with a foam sleeve for wet jobs. Without it, the 72 dB jumps to 80+ dB as water sloshes in the tank.

Real-world use case: Electricians love its 25-ft cleaning reach for pulling wires in occupied buildings (clients never hear it running).

DEWALT DWV015 10-Gallon HEPA Dust Extractor

When OSHA compliance is non-negotiable (think concrete polishing or lead abatement), this 80 dB unit is worth every penny. Don't let the dB number fool you. Its automatic filter cleaning pulses every 30 seconds, preventing the suction drop that makes vacs scream louder as they clog. The real noise win? DEWALT's AirLock system seals all connections, eliminating the 5-7 dB penalty from adapter leaks.

Critical for your kit: You must add fleece bags (DWV9402) and HEPA filter (DWV9330) for silica work. Without them, it's just another loud vac.

Step 3: Noise Reduction Techniques That Actually Work On Jobsites

Your vacuum alone won't solve noise issues. Implement these field-tested tactics:

Tactic 1: Muffler + Diffuser Combo

Ridgid's $15 muffler (model 29008) cuts noise by 3-5 dB and solves blowback, a win for client relations. But here's what manuals omit: always pair it with a diffuser. Without it, redirected air scatters dust back onto clean surfaces. I've seen crews save $200+ in callback cleanups by adding this $8 attachment.

Tactic 2: Anti-Static Hose Upgrades

Standard PVC hoses generate static that amplifies noise by 2-4 dB (and shocks workers). Swap to conductive rubber hoses like the Vacmaster ProFlex (included with their Beast Series). The denser material dampens sound and grounds static (critical near electronics or flammable dust).

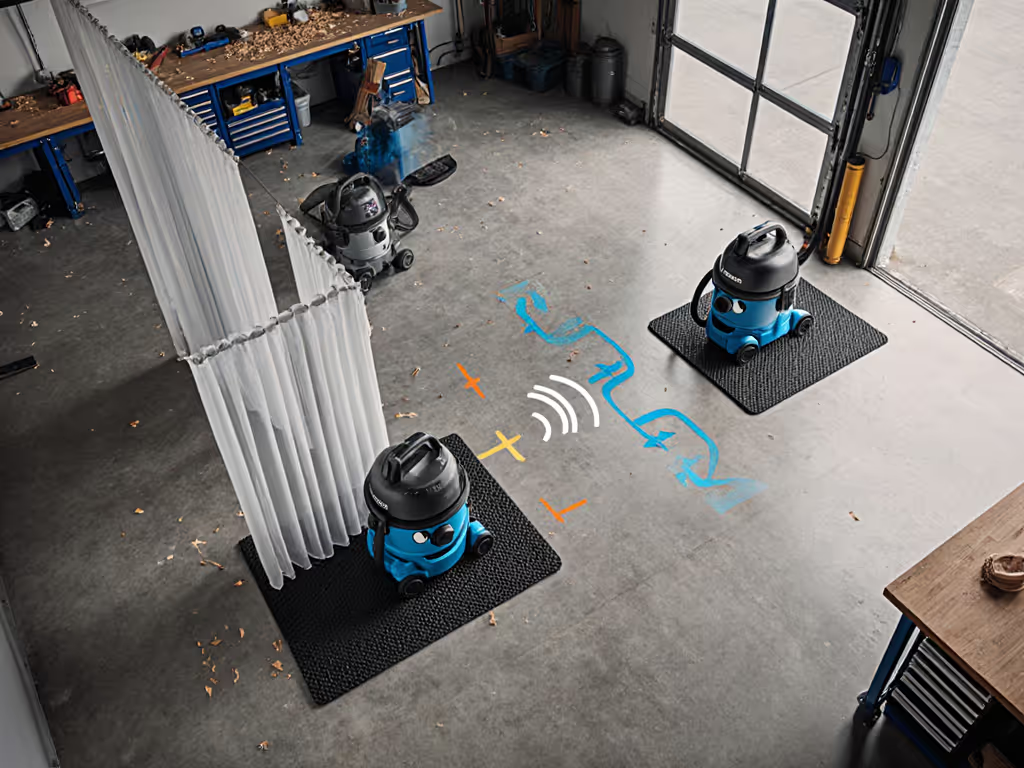

Tactic 3: Strategic Placement

Place vacs:

- Behind walls/curtains where possible (reduces perceived noise by 10 dB)

- On rubber mats to kill vibration noise (OSHA tip from 1926.52(d))

- Downwind of occupied areas to use airflow as a noise barrier

The Bottom Line: Quiet = Compliance + Client Trust

A "quiet" vacuum isn't a luxury; it's operational hygiene. When I audit sites now, I check dB levels before filter specs. If the crew isn't wearing ear protection (because the vac's "quiet enough"), airborne dust exposure skyrockets. The Vacmaster Beast Series and RIDGID 4000RV prove affordable hearing protection vacuum solutions exist. But remember: decibel levels shop vac specs mean nothing if joints aren't sealed or filters are mismatched.

Final site-ready checklist:

- Verify dB rating with your hose/tool combo (not just bare unit)

- Install HEPA filter and foam sleeve for wet/dry versatility

- Tape all adapter joints (even "locking" ones leak)

- Store muffler/diffuser on the unit (no searching mid-job)

Seal every joint on purpose. Your crew's hearing, and your next job referral, depend on it. For deeper dives into OSHA-compliant dust control systems, explore our HEPA filtration guide or [site-ready vacuum kit templates].